Step 1.7 Options generation and feasibility analysis

Which techniques can be utilized to generate a set of resource efficiency measures?

Rationale

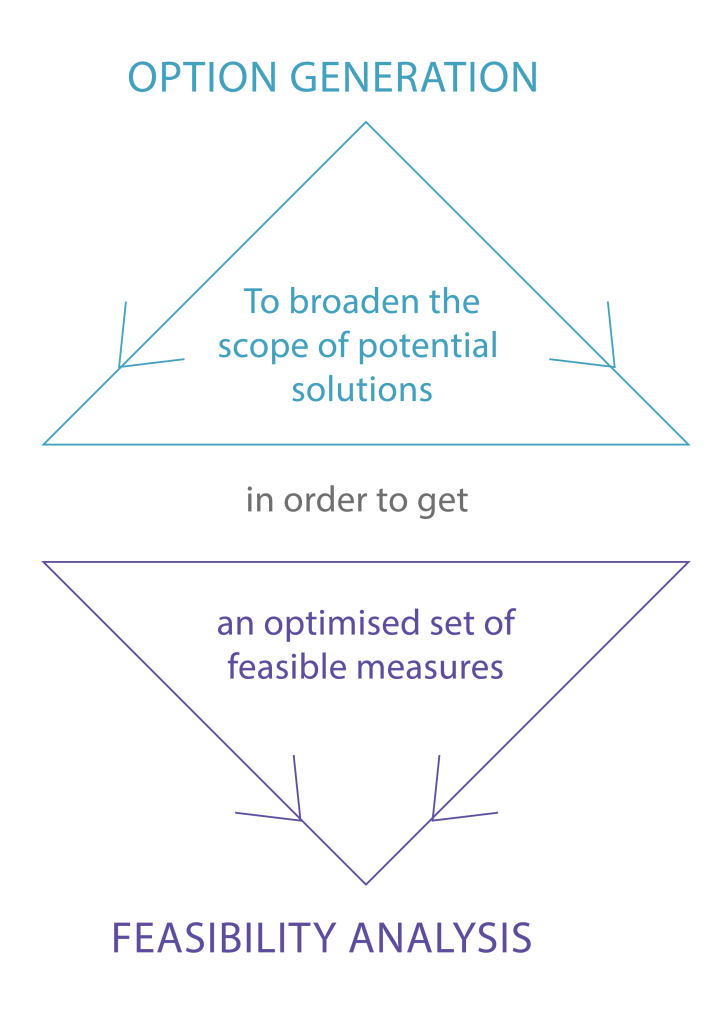

This step builds on the root causes of significant material and energy losses identified in the previous step. It starts by broadening the scope of potential solutions by generating a broad menu of possible options and then narrowing the menu down to an optimal set of feasible measures to be subjected to feasibility studies, as illustrated in the figure.

Options generation

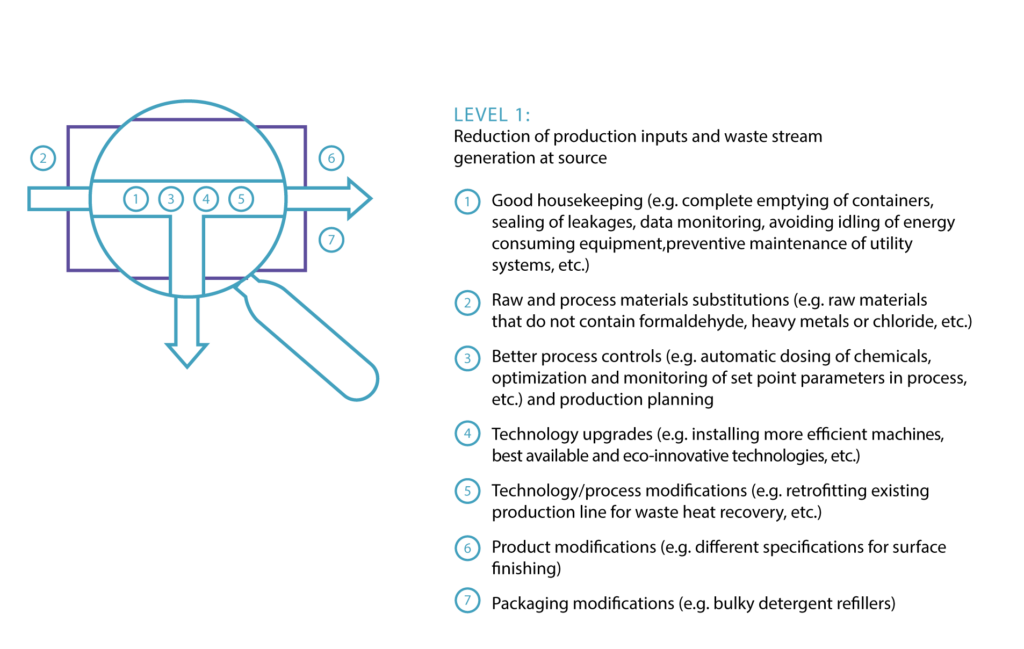

Once the company diagnosis in step 1.6 has been completed, possible options for improvement can be generated effectively. A brainstorming approach should be used, where the participants should be encouraged to think “outside the box” as much as possible, and where the proposing of options, even radical ones, should be encouraged. Options can be explored according to the hierarchy shown in the figures below .

The TEST Team should first focus on identifying options which prevent NPOs from being generated in the first place or, failing that, which minimize them (so-called reduction at source). Such options fall into the categories of good housekeeping, changing input specifications, improving process control, modifying equipment, changing technologies, and modifying products, turning wastes into by-products, and onsite reuse and recycling of wastes.

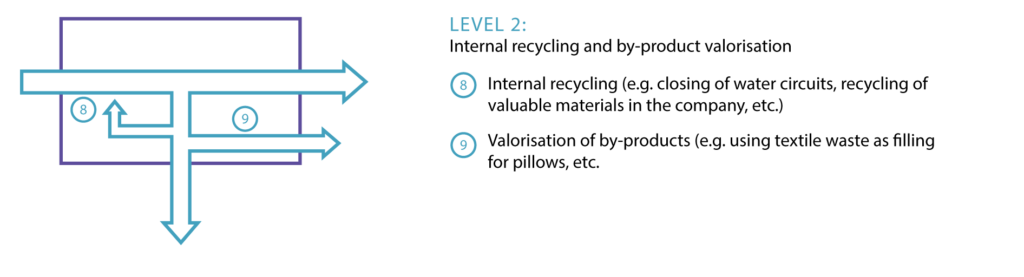

Techniques for internal recycling and valorisation of by-products can be considered next.

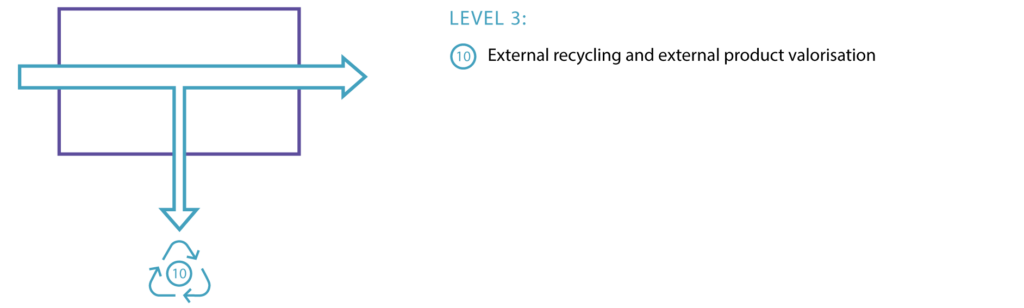

While external recycling leads to a reuse of a waste and thus a reduction in environmental impacts, it does not reduce NPO and it entails risks to the environment during transport off the site to a new site of use as well as in processing to make it reusable. This is why these techniques should be investigated at a later stage after the economically most feasible preventive solutions have been explored.

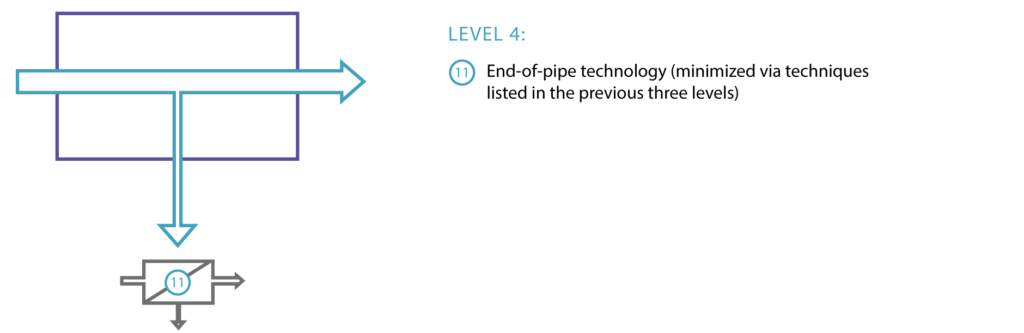

Pollution and waste treatment options (also called end-of-pipe solutions) should be investigated at the very end. While these kinds of solutions are often required to comply with emission limit values and waste management requirements, even after preventive solutions have been adopted, they require high capital expenditures, have continuing operational costs, and show no return on investment. By following this hierarchy, the TEST Team can substantially reduce, and in some cases eliminate, the investments and operational costs for end-of-pipe solutions.

Feasibility analysis

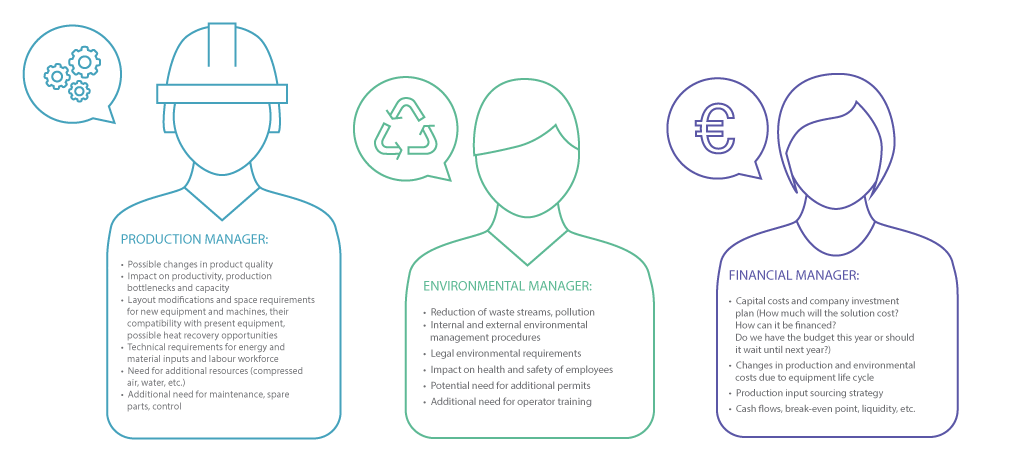

The TEST Team can now assess the feasibility of the options which they have identified. To do so, they will use technical, environmental and economic criteria in order to decide on the optimal set of options for the company to implement as part of its TEST action plan. The TEST Team should bring in the perspectives of different internal stakeholders as indicated in the figures below.

The TEST Team will first use technical and environmental criteria to exclude options that might have an adverse impact on product quality or might cause cross-media environmental side effects that could potentially offset the expected environmental benefits.

For those options surviving the technical and environmental assessment, the TEST Team will carry out a cost-benefit analysis. This analysis will quantify the economic savings from implementing each option, the capital expenditures required to implement the option, the change in operating costs brought about by implementing the option, and finally the return on investment. With respect to the economic assessment, options can be classified into three main categories:

- Good housekeeping measures, requiring little or no cost to implement;

- Low-medium cost measures, which can be implemented using the company’s own technical and financial resources;

- High cost measures that might require external financing. These measures normally entail an initial prefeasibility study and a subsequent more complex technical and financial appraisal that is often carried out by the company.

Resource efficiency criteria can assist companies in optimizing basic technological parameters and identifying the most appropriate technology providers from a range of suppliers on the market.

The outcome of the feasibility analysis is the “savings catalogue”, which the TEST Team will submit to top management for their review and approval. This provides the technical description and the key economic and environmental indicators for the set of feasible improvement measures which the TEST Team recommends to be implemented. This set of measures is usually a mix of good housekeeping measures, measures to improve operational control, modifications of the existing technology, as well as investment in new equipment.

ACTION TABLE ►

TIPS ►

- The focus of options generation should be on generating as many options as possible, including any ideas that have already been generated in the previous TEST steps.

- It is good practice to also keep a record of rejected options for possible future use and/or for inspiration during the next round of innovation efforts.

- Brainstorming is an effective and recommended technique for options generation, as it leverages the variety of expertise in a team and overcomes barriers to the open sharing of ideas and mutual inspiration. If people are hesitant to express their ideas during a shared session, ideas could be individually recorded from different team members. A brainstorming workshop involving not only the TEST Team, but also others, including, for example, an external expert, who can be useful in generating options for complex focus areas.

- Emission and pollution reductions for specific measures can be difficult to estimate for an accurate estimation of savings. Pollution intensity benchmarks are available in the literature (e.g. EU BREFs) for some products (e.g. BOD5 per m3 of milk).

- MFCA data can be used during the economic feasibility assessment. Moreover, a sensitivity analysis could be performed if relevant changes in the business environment are expected in the short to medium term (increasing environmental management costs due to enforcement of new legislation, removal of subsidies on energy/water prices, increase in the price of important raw materials, etc.).

- Detailed technical studies for investigating the feasibility of complex options and/or those requiring high investment can be listed and budgeted at this stage already – and integrated into the TEST action plan.

- The savings catalogue of feasible measures should also include measures for improving the information systems on material and energy flows in the company.